|

Henan Huineng Road And Bridge Technology Co.ltd.

|

Best concrete waterproof repair mortar

| Price: | 1000.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

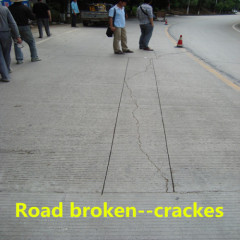

Aiming at solving concrete water leakage in wharf,

bridge girder, highway,pond,roof,bathroom

Best concrete waterproof repair mortar

TL - 02 type cement concrete patching material, composed by high quality special cement, fine graded silica sand and imported polymer,inorganic gelled material and a variety of function additives, is a kind of repair mortar specializing in patching road, bridge, passenger railway and bridge beam.The material, with high early strength, excellent flexibility and cohesive force, meet the requirements and durability of high grade highway and other high-speed rail project . It's widely used in concrete pavement structure, track plate, bridge plate and bridge pier defect repair and reinforcement, especially suitable for concrete pavement, the high speed railway box girder, bridge deck defect repair.

Suit for:

1.Concrete defects of high grade road.

2. Flatness of high-speed railway and bridge deck.

3. Repair and reinforce defects of concrete structure(bridge body, bridge pier or abutment)

4. Surface cracking and chip off-falling of concrete beam, load-bearing column and outdoor sheet.

Adwantage:

1. Achieved 1-2 h rapid open to traffic.

2. Good leveling property.

3. High strength in early and later period: compressive strength of 4h>30Mpa, compressive strength of 1d >50Mpa, compressive strength of 28d>70Mpa.

4. Good bonding performance: concrete mortar can obtain high bonding strength and excellent cohesive force without interface agent.

5. Frost resistance, sulfate corrosion resistance, non-toxic, non-corrosive.

6. Good anti-cracking performance:adapt to the deformation of the concrete basement without cracking or peeling. No crack, shell, stripping when thin layer repair.

7.Can be used in damp base course and damp environment as first-aid repair material.

Packing and storage:

1.Packing: paper bag packing, 25Kg/bag

2.Storage:store in cool,dry place, use Moisture-proof insulation at bottom, top with

plastic to prevent water,keep ventilation, avoid direct sunlight.

3.Storage period: 9 months.

The detected value (28 days)

Inspection items | Unit | Technical requirement | Inspection result | Individual conclusion | |

Setting time | Initial setting | Min | ≥20 | 25 | Meet requirement |

Final setting | ≤50 | 45 | |||

Compressive strength | 4h | Mpa | ≥20 | 41.0 | Meet requirement |

1d | ≥40 | 56.1 | |||

28d | ≥50 | 76.5 | |||

Pull strength | 28d | Mpa | ≥2.5 | 2.7 | Meet requirement |

Expansion rate | 28d | Mpa | 0.02%-0.1% | 0.06% | Meet requirement |

packaging and storage

1)Package: Paper plastic composite bag packaging, 25Kg/bag.

2)Storage: Store in a cool, dry place, rainproof and moistureproof.

3)Storage period: 9 months

.jpg)

.jpg)