|

Henan Huineng Road And Bridge Technology Co.ltd.

|

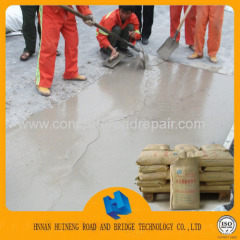

The best materials and repair scheme to repair the bridge deck crack

| Price: | 1200.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1,Rapid setting-2 hours canopen the traffic

2,High compressive

3,good adhesion properties

4,Drawing high strength

5,Easy to use

The best materials and repair scheme to repair the bridge deck crack

I. Introduction

Deck concrete repair material (QM type) is a high-tech strength and good toughness rapid repair material, ideal material suitable for highway, national, provincial, municipal roads rapid repair of the bridge. The Department of Science and Technology in Henan can bridge cement potholes Treatment, Treatment cement pavement crack, crack Treatment bridge deck Treatment potholes, broken concrete bridge expansion joints, potholes, cracks quickly repair areas with core technology! Realized 1h - 2h fast open traffic!

Second, the product 8 big advantage

A fast recovery of traffic: for high-speed, national, provincial, municipal, airports and other transportation can be achieved 1--2 hours.

2, high compressive strength: 1h more than 25Mpa, 2h more than 35Mpa, 1d more than 60Mpa, 28d more than 80Mpa.

3, high flexural strength: 1h greater than 5Mpa, 2h greater than 7.5Mpa, 1d more than 10Mpa, 28d more than 11Mpa.

4, good adhesion properties: bond pull strength reaches 2.8Mpa, to solve the traditional material bond is not strong or problems can easily lead hollowing cracks.

5, the product toughness and impact resistance: 5-10 times that of ordinary concrete.

6, the thermal expansion coefficient: basically consistent with the primary concrete.

7, no shrinkage cracks: between the original concrete and no shrinkage cracks after solidification.

8, frost and salt corrosion: cold-resistant, corrosion-resistant sulfate, non-toxic, non-corrosive.

Third, the construction method :( graphic combination)

Construction process:

Traffic Control → Logo → crossed → kerf → chiseled scour → cleanup cleanup → protection → spices → Patch → slitting → conservation → relieve traffic control

Fouth. Notes:

1. The cement concrete pavement repair materials for the early strength materials, operative time is usually less than 15 minutes; user needs based on the operating time adjustable material; hardened mortar is strictly prohibited.

2. Add clean diameter ≤30㎜ graded gravel aggregate, the ratio was 50%.

3. Construction of the summer has been good repair area surface should prevent exposure, can be patched plastic film covering the surface area;

4. Winter conservation should pay attention to insulation, hot water can be stirred and stamped with rockwool insulation, the temperature is below 5 ℃, or wind or rain can not be greater than 5 construction.

V, the detected value (28 days)

Test items | Unit | Technical Requirements | Test results | Individual conclusions | |

Setting time | Initial setting | Min | ≥20 | 25 | Meet the requirements |

Final setting | ≤60 | 30 | |||

Compressive strength | 2h | Mpa | ≥20 | 33.0 | Meet the requirements |

1d | ≥40 | 66.1 | |||

28d | ≥50 | 90.5 | |||

Drawing strength | 28d | Mpa | ≥2.0 | 2.8 | Meet the requirements |

Expansion | 28d | / | 0.00%-0.1% | 0.01% | Meet the requirements |

Sixth, packaging and storage

Paper-plastic bag, 25Kg / bag; store in a cool dry location, rain, moisture barrier, the storage period of 9 months.

.jpg)

.jpg)