|

Henan Huineng Road And Bridge Technology Co.ltd.

|

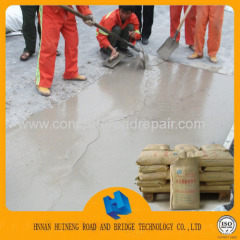

The easy way to repair the bridge deck crack broken with huineng concrete rapid repair mortar

| Price: | 1200.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1,Rapid setting-2 hours restore the traffic

2,High compressive strength

3,good adhesion properties

4, high drawing strength

5,Easy to use

The easy way to repair the bridge deck crack broken with huineng concrete rapid repair mortar

Product introduction

QM type concrete bridge deck repair material is a kind of high strength and toughness good high-tech concrete rapid repairing materials that gathered by Henan Huineng road and bridge technology Limited .Suitable for expressway, national highway, provincial way, municipal bridge deck crack treatment, bridge pothole treatment, bridge expansion joints concrete crushing , hole, crack rapid repair.Our Company has the core technology to realize the fast restored the traffic in 1 - 2 hours!Resolve the problems of bridge deck construction lead to traffic jams.Meet the high quality and the durability repair requirement of high grade highway, national highway, provincial highway bridge .

QM type bridge deck concrete repair material is a kind of one-component special repair material, The construction of the materials is simple, high strength, good toughness and cohesive force strong, Not broken and not fall off under the high speed, high pressure, impact of traffic condition.

Scope of application:

1, Bridge surface layer pothole, crack rapid repair;

2, Bridge expansion joint concrete crushing, hole, crack rapid repair ;

3, Expressway, national highway, provincial highway, airport, municipal engineering, tunnel concrete pavement pit, serious cracks, voids, fracture crack etc. severe damage rapid repairing;

Product advantage:

1, Achieve rapid restore traffic in 1-2 hours.

2, High compressive strength: more than 25 mpa in 1 h, more than 35 mpa in 2 h, more than 60 mpa in 1 day.

3 ,High flexural strength: more than 5 Mpa in 1 h, more than 7.5 Mpa in 2 hour, more than 10 Mpa in 1 day.

4 Cohesive force strong: not appear the empty drum or crack.

5, Product toughness and shock resistance: 5 to 10 times than ordinary concrete.

6, Coefficient of heat bilges cold shrink, consistent with the grass-roots level concrete.

7, No drying shrinkage crack: no the drying shrinkage with the original concrete after solidification

8, Antifreeze and corrosion resistance: resistance to freezing, sulphate corrosion resistance, non-toxic, non-corrosive.

The construction process:

Traffic control→ identify→lineation→joint-cutting→Chisel except→clean→scour→protection

→Mixing materials→repatching→joint-cutting→maintenance

The detected value (28 days)

Test items | Unit | Technical Requirements | Test results | Individual conclusions | |

Setting time | Initial setting | Min | ≥20 | 25 | Meet the requirements |

Final setting | ≤60 | 30 | |||

Compressive strength | 2h | Mpa | ≥20 | 33.0 | Meet the requirements |

1d | ≥40 | 66.1 | |||

28d | ≥50 | 90.5 | |||

Drawing strength | 28d | Mpa | ≥2.0 | 2.8 | Meet the requirements |

Expansion | 28d | / | 0.00%-0.1% | 0.01% | Meet the requirements |

packaging and storage

1)Package: Paper plastic composite bag packaging, 25Kg/bag.

2)Storage: Store in a cool, dry place, rainproof and moistureproof.

3)Storage period: 9 months

.jpg)

.jpg)